经验分享|2006年-2018年EDQM检查和缺陷趋势概述

2006年-2018年EDQM检查和缺陷趋势概述

1) INTRODUCTION 概述

All sites involved in the manufacturing of Active Pharmaceutical Ingredients (API) for which a CEP has been requested or granted may be subject to an inspection by the EDQM. A negative outcome of an inspection may result in actions against related CEPs (suspension or withdrawal ofCEPs or closure of CEP applications). Re-inspections are performed either to verify the return tocompliance after a negative inspection outcome, or in the context of

monitoring the sustainabilityof the GMP status.

所有参与生产已申请或批准CEP的活性药物成分(API)的工厂都需要接受EDQM的检查。检查的负面结果可能导致官方对CEP证书采取行动(暂停或撤销CEP或关闭CEP申请)。重新检查的目的是在负面检查结果后,或在监测药品生产质量管理规范状态的可持续性的背景下,验证是否符合要求。

This document is a review of data from API inspections conducted by the EDQM between 2006 and 2018. It covers:

本文件是对EDQM在2006年至2018年间进行的API检查数据的回顾。它涵盖了:

the location of the inspections;

检查地点;

whether they were initial or re-inspections;

初步检查还是复检查;

their outcome;

检查结果

the distribution of the observed deficiencies to EU Good Manufacturing Practice (GMP) Part II area and criticality;

观察到的缺陷在欧盟良好制造规范(GMP)第二部分的分布和关键性;

the frequency of the findings;

调查结果的频率

issues of data integrity.

数据完整性问题

The deficiencies observed during EDQM inspections are referenced to EU GMP Part II and therelevant Annexes,or to the corresponding CEP dossiers and the European Pharmacopoeia (Ph.Eur.) in general.

EDQM检查期间发现的缺陷参考欧盟GMP第二部分和相关附件,或相应的CEP档案和欧洲药典(欧洲药典)。

2) REVIEW OF INSPECTIONS BY LOCATION, HISTORY AND OUTCOME

审查检查情况、依据、历史和结果

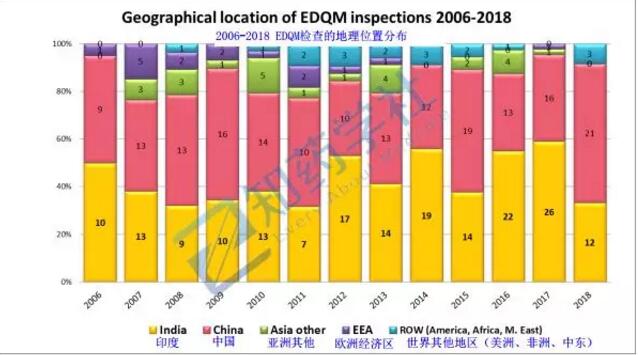

2.1 The distribution of EDQM inspections by geographical location of inspected sites is given in the followingchart:

下表给出了按受检地点地理位置划分的EDQM检验分布情况:

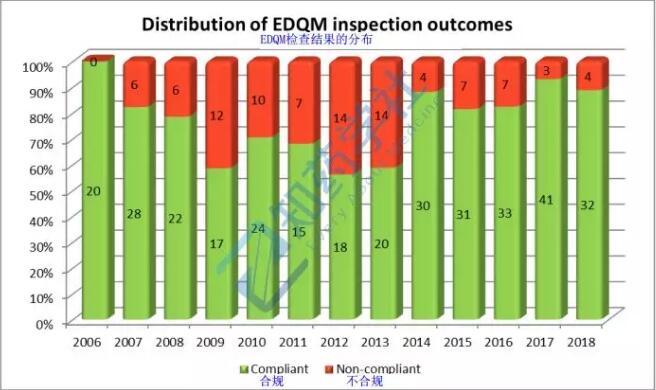

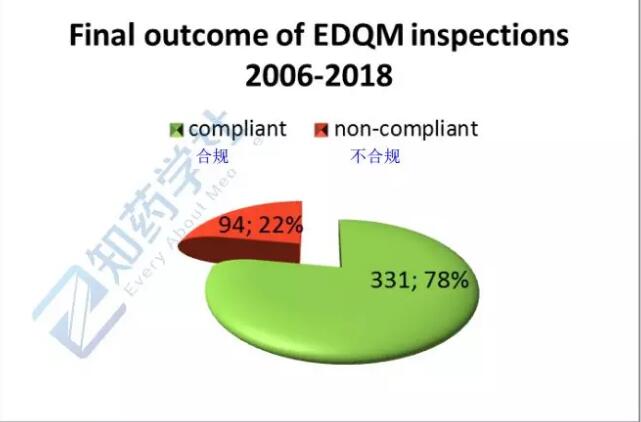

2.2 The distribution of outcomes of EDQM inspections is given in the following chart:

EDQM检查结果的分布如下图所示:

The chart below displays the total number and ratio of outcomes of EDQM inspections during thereview period:

下表显示了在审查期间EDQM检查结果的总数和比率:

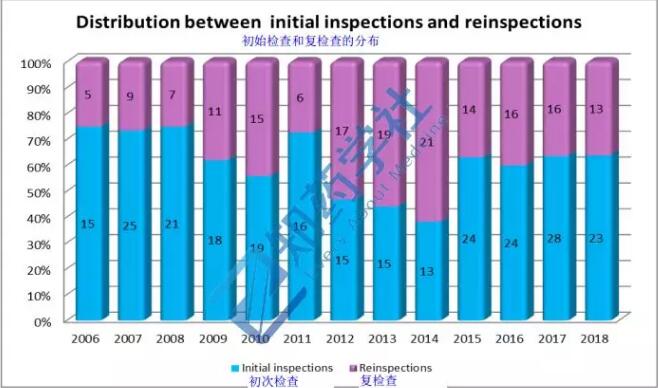

2.3 The distribution of EDQM inspections (initial or re-inspections) is given in the following table:

EDQM检查(初始检查或复检查)的分布如下表所示:

3) DISTRIBUTION OF DEFICIENCIES BY GMP AREA (including compliance with

CEP) & CRITICALITY

按GMP区域划分的缺陷分布(包括符合CEP)和关键性

The deficiencies reported during EDQM inspections are classified as critical, major or other,depending on the risk they may pose to public health and the degree of deviation from EU GMP,the relevant CEP dossier and European Pharmacopoeia (Ph. Eur.).

EDQM检查过程中报告的缺陷可分为关键缺陷、主要缺陷或其他缺陷,具体取决于这些缺陷对公众健康造成的风险以及与 欧盟GMP、相关CEP档案和欧洲药典(欧洲药典)的偏离程度。

For this review, they have been distributed according to the respective chapters of EU GMP PartII as well as compliance with the CEP dossier and the Ph. Eur. Some items group several chapters of the EU GMP Part II.One item gathers all CEP dossier and Ph. Eur. compliance issues.The grouping aims at avoiding the variability linked with the fact that some deficiencies may berelated to different chapters.

在本次审查中,它们是根据欧盟GMP PartII的相关章节以及与CEP档案和欧洲药典的一致性进行划分的。

Only the numbers of the EU GMP Part II chapters are mentioned for each group in the charts; forthe detailed grouping,see Annex I.

图表中只提到了欧盟GMP PartII各章的编号,详细分组见附件一。

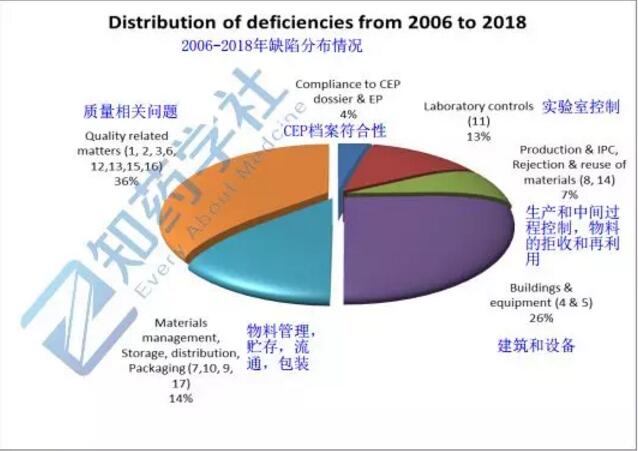

3.1 The overall distribution of deficiencies from EDQM inspections between 2006 and 2018 by GMP area and CEP compliance is displayed in the chart below:

下表显示了2006年至2018年EDQM检查中GMP领域和CEP合规性的缺陷总体分布情况

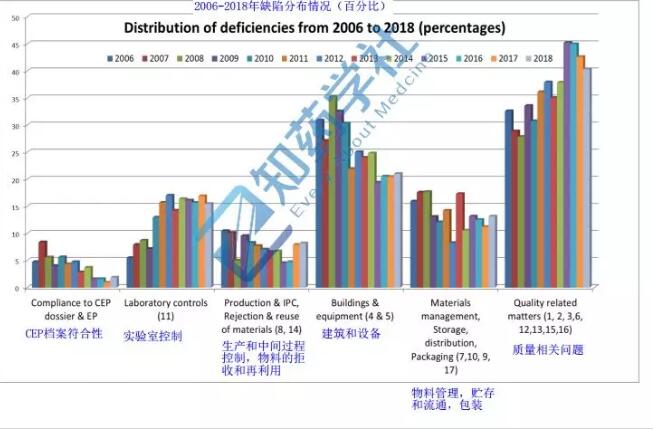

3.2 The chart below displays the trends in the deficiencies throughout the years by GMP area and CEP compliance (percentages of the total number of deficiencies for each year):

下表按GMP领域和CEP合规性显示了全年缺陷的趋势(每年缺陷总数的百分比):

The following trends can be seen from the chart:

从图表中可以看出以下趋势:

Quality related matters: overall increase until 2015 (up to 45% from 32% in 2006), slight drop since then (down to 40% in 2018);

质量相关问题:到2015年总体增长(从2006年的32%上升到45%),此后略有下降(2018年下降到 40%)。

Materials management: initially variable, overall stable since 2014 (10-13%);

物料管理:初始变化无常,2014年以来总体稳定(10-13%)

Buildings and equipment:decrease from 2008(35%),overall stable since 2015(19% to 21%);

建筑和设备:较2008年下降(35%),2015年以来总体稳定(19%至21%)

Production: consistent decrease until 2016, increase in 2017-2018 (from 5% to 8%);

生产:至2016年持续下降,2017-2018年增长(5%至8%)

Laboratory controls:generalincrease until 2012 (17%), overall stable since;

实验室控制:2012年前总体增长(17%),此后总体稳定;

Compliance to CEP dossier and Ph. Eur.: regular decrease (from 8% in 2007 down to 1%in 2018)

CEP档案和药典符合性:有规律下降(从2007年的8%降至2018年的1%)

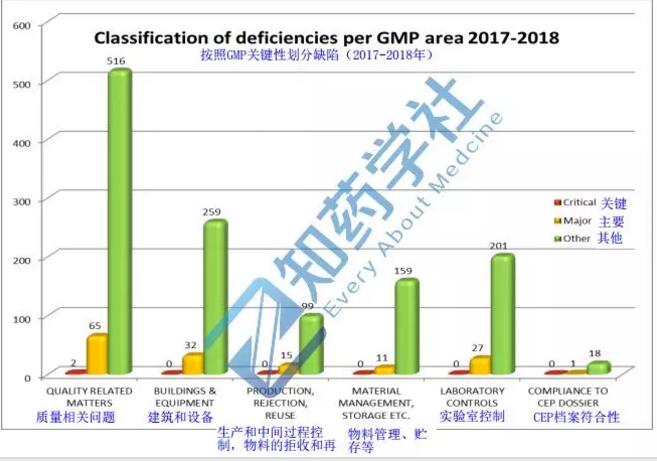

3.3 For recent inspections (2017-2018) the number of deficiencies by level of criticality(critical, major and other) in each GMP area have been analysed and are presented in thechart below.

对于最近的检查(2017-2018年),每个GMP领域的关键性(关键、主要和其他)级别的缺陷数量已进行了分析,并在下面的图表中列出。

It can be seen from the chart that the largest occurrence of major and critical deficiencies isobserved in Quality related matters, followed by Buildings & Equipment, and by Laboratory controls in third place (details in section 4).

从图表中可以看出,质量相关问题中出现的主要缺陷和关键缺陷最多,其次是建筑和设备,以及实验室控制排第三(详情见第4节)。

It should be pointed out that the combination of major findings may lead to an overall critical riskfor public health (and therefore a non-compliant inspection outcome without individual critical deficiencies), which is not reflected in the chart.

应当指出的是,主要发现的组合可能会对公众健康造成总体的关键风险(因此,不符合要求的检查结果没有个别的关键缺陷),这在图表中没有反映出来。

4) MOST FREQUENT TYPES OF DEFICIENCIES BY GMP AREA

按GMP领域划分的最常见缺陷类型

The most frequent types of deficiencies identified in each GMP area during EDQM inspections between 2006 & 2018 are listed below.

下表列出了2006年至2018年EDQM检查期间在每个GMP领域发现的最常见缺陷类型。

4.1 Quality related matters 质量相关问题

Insufficiency and/or ineffectiveness of quality system rendering operations not reliable asevidenced by:

质量体系的不足和/或无效导致操作不可靠

Insufficient oversight of quality unit over GMP activities, e.g.:

质量部门对GMP活动的监督不足,例如:

failure to effectively control documentation (both paper and electronic);

未能有效控制文件(纸质和电子文件);

inadequate overview of production and laboratory activities;

生产和实验室活动概述不充分;

underreporting and/or insufficient investigation of quality events(complaints,

deviations, out-of-specification (OOS) results, change controls);

质量事件(投诉、偏差、超标(OOS)结果、变更控制)的报告不足和/或调查不足;

Fraudulent documentation practices, e.g.

欺骗性文件,例如:

rewriting documents in order to demonstrate acceptable, expected or presentableresults, values or dates;

重写文件,以证明可接受、预期或可呈现的结果、数值或日期;

untimely recording of operations;

操作记录不及时;

unavailability of records;

记录不可用;

use of loose sheets instead of bound logbooks;

使用活页代替装订的日志;

Quality Risk management principles not applied or inadequately implemented in areas such as production activities, deviations, change control, etc.

质量风险管理原则在生产活动、偏差、变更控制等方面未得到应用或实施不充分等。

Annual quality review not used as a quality tool by companies, e.g.:

公司未将年度质量回顾作为质量工具,例如:

not all batches reflected (especially “non-CEP” grade, even though manufactured by same process);

并非所有批次都反映出来(尤其是“非CEP”级,即使采用相同工艺制造);

trends not detected or investigated;

未发现或调查的趋势;

Insufficient personnel training, e.g.:

人员培训不足,例如:

no training given to upper management with regard to GMP related matters;

未对上级管理人员进行与GMP有关的培训;

no assessment of training’s efficiency or with limited value;

未评估培训的效果或培训价值有限;

Insufficient validation, e.g.:

验证不足,例如:

processes such as use of recovered solvents, blending or micronisation not always addressed;

诸如使用回收溶剂、混合或微粉化等过程并不总是被提及;

lack of sound knowledge of different approaches regarding cleaning validation.

对清洁验证的不同方法缺乏足够的了解。

Production生产

Blending of batches without prior appropriate testing;

在没有经过适当测试的情况下混合批次

Lack of control of solvent recovery.

缺乏对溶剂回收的控制

4.5 Laboratory controls 实验室控制

Fraudulent practices regarding testing activities, e.g.:

有关实验室控制活动的欺骗行为,例如

pretesting or “testing into compliance”;

预测试或“测试合规”

deleting OOS results;

删除OOS结果

unreliability of analytical results;

分析结果不可靠

Unreliable microbiological results;

不可靠的微生物结果

Issues with Chemical Reference Standards (CRS):

关于化学参考标准( CRS)的问题

absence of the Ph. Eur. CRS;

没有欧洲药典,化学参考标准

insufficient establishment of secondary standards;

二级标准制定不足

Lack of proper monitoring of potable water.

缺乏对饮用水的适当监测

全部 0条评论